Mill (grinding) Wikipedia

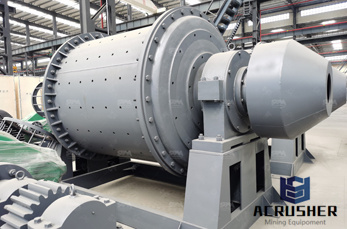

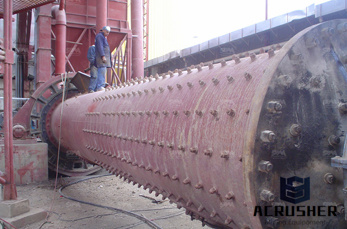

Ball mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually ...

WhatsApp)

WhatsApp)

Ball mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually ...

DEVELOPMENTS IN AG/SAG MILL MODELLING ... relate the breakage rate to operating conditions such as ball load, ball size and mill ... Typically the load level that ...

The first step is to recognize the relationship between the ball mill circuit circulating load ratio (CLR) and the overall circuit capacity or efficiency.

ARE SAG MILLS LOSING MARKET CONFIDENCE ... Different combinations of SAG mill ball charge and grate open area were tested until 2006. A higher load level was ...

An efficient pulp lifter for agsag ... 181 for the same level of holdup in the mill. ... Gross power Power usage Total load Ball load Rock and slurry Mill ...

Optimisation of the secondary ball mill using an online ball and pulp load ... Although the pulp level remains almost constant the ball load appears to expand ...

Ball Mill Online Estimation of Inmill Slurry Density. ... The ball level was ... Ball load average lift angle, mill absorbed power and slurry density variations

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Ball Mill Loading (dry milling) When ... As with most of the independent variable in ball milling it is best to do some ... you can simply load the mill with the ...

Ball Mill Bearing, Wholesale Various High Quality Ball Mill Bearing Products from Global Ball Mill Bearing Suppliers and Ball Mill Bearing Factory,Importer,Exporter ...

In order to measure the ball load in the mill, ... and the % ball level was measured ... as to maintain the total ball load in the mill. Stocks of replacement balls

Ball mills account for the majority ... Parameters that hold potential energy savings are load level, ... Optimizing the operation of the cement mill; Optimizing the ...

Ball Mill Electronic Vibration measuring systems for control, fill level and process optimization in Mining and Cement.

The optimum composition of the makeup ball sizes in ball mills is presented. • The effect of various factors was investigated via a grinding circuit simulation.

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

8 Advanced Simulation for SemiAutogenous Mill Systems: A Simplified Models Approach José Luis Salazar1, Héctor ValdésGonzález1 and Francisco Cubillos2

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... A simplified picture of the mill load is shown in Figure ... Figure Effect of mill filling on power draft for ball

MILLING CONTROL OPTIMISATION ... Millstar Ball Load Estimator Millstar Mill Power Filter ... Detection for Level Signals, Density,

dynamic load of ball mill Crusher South Africa calculation of loads from vibrating screen. KnelsonSizetec Vibrating Screens Knelson Gravity Solutions ... KnelsonSizetec ...

It is difficult to generalize on SAG mill ball size selection as it depends on a number of factors some of which are listed in the below checklist:

Pigment Ball Mill, Pigment Mill, Pigment Powder Grind . Working Principle . X QM series planetary ball mill has four ball grinding tanks installed on one turnplate.

Ball mill is the main equipment of ore dressing process, and it is widely used in mining, metallurgy, building materials, refractory, cement, chemical and thermal ...

EXPERIENCE WITH SYNCHRONOUS AND Ball mill load characteristics low level of material in the mill at start. Service Online. Previous:premium manganese crusher

Keeps ball load at constant level. Ensures continuous grinding ball loading to the mill. Increases mill autonomy in regards to grinding media charging.

WhatsApp)

WhatsApp)